Cartridge Type Industrial Dust Collector, High Efficiency Dust Extractor System

- Model

- TR-Series

Item specifics

- Power Supply

- 380V/50HZ or customize

- Filter Material

- Polyester Cartridges

- Dashing Mode

- Pulse jet compressed air backflowing

- Compressed Air Source

- 0.4-0.6MP

- Timer Jet Control

- Time control

Review

Description

Video

Usage

Removes dust from pulverizing and grinding, crushing, sanding, powder injection and sealing, severing and cutting, stone and metal work, cutting work, substrate work and welding work...

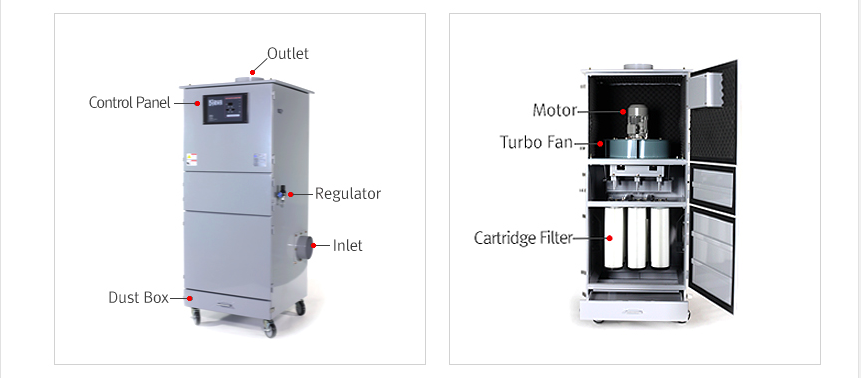

High Efficiency System

-The structure of the filter designed in a cartridge type increases the filtering area and maximizes the collection efficiency of fine dust.

-Various types of filter media can be design to suit the type, characteristics and particle of the dust generated in different working environments.

Turbo Ventilator

-Special alloy is applied to reduce the idle weight and starting a load and, thus, increase the absorption force, and electronic balancing with the mode has achieved zero-vibration and low-noise.

-Eliminates the vibration caused by dirt squeezed in-between or stuck to the fan wings during use.

Filter Cleaning Method

-The dust attached on the cartridge filter is sprayed into the inside of the cartridge filter automatically by compressed air injection( air pulse), heightening the dust exhaustion efficiency.

-The dust collector eliminate dust in an automatic fashion, which makes the 24-hours continuous operation possible.

Pulse type digital differential pressure measurement control system

-Equipped with a high-functioning stabilized digital measurement system for dust collectors by digitally integrating the solenoid valve timer;

-Distant/local mode: could control remotely.

Specification

Model(B) | Air volume(m³/h) | Filter(㎡) | Fan pressure(Pa) | Power(kw) | Air Source | Sound(dB) | |

TR-8B-II | 500-900 | 12 | 1780 | 0.75 | 0.4~ | 0.6MP | 65 |

TR-10B-II | 900-1100 | 12 | 2040-1780 | 1.1 | 0.4~ | 0.6MP | 67 |

TR-15B-II | 1400-1600 | 18 | 2040-1780 | 1.5 | 0.4~ | 0.6MP | 70 |

TR-25B-II | 1688-2476 | 30 | 2150-1820 | 3 | 0.4~ | 0.6MP | 73 |

TR-30B-II | 2664-3405 | 30 | 2700-2200 | 4 | 0.4~ | 0.6MP | 73 |

TR-40B-II | 3786-4527 | 36 | 2700-2200 | 5.5 | 0.4~ | 0.6MP | 75 |

TR-60B-II | 4973-6457 | 48 | 2700-2200 | 7.5 | 0.4~ | 0.6MP | 75 |

TR-80B-II | 7081-8489 | 60 | 2700-2200 | 11 | 0.4~ | 0.6MP | 78 |

TR-100B-II | 8490-10455 | 75 | 2790-2020 | 11 | 0.4~ | 0.6MP | 80 |

TR-120B-II | 10400-13455 | 90 | 2790-2020 | 15 | 0.4~ | 0.6MP | 85 |

Product Question and Answer

Q: What should provide when choosing suitable dust collectors?

A: Process summary sheet should be provided, for we need to know the dust collection summary for example: dust category (what? Flammable? Corrosive? Explosive? Temperature? Density?)

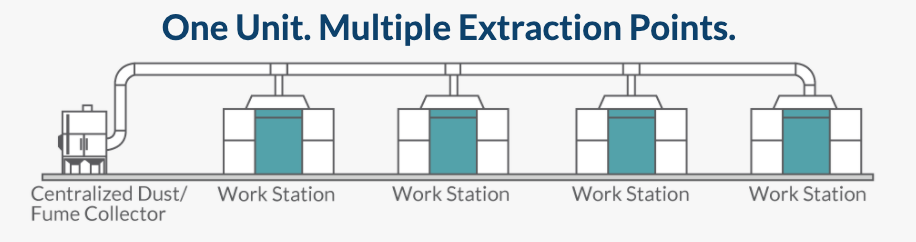

Q: How to confirm the airflow/air capacity and the pressure?

A: Mostly, it depends on the dust suction hoods, then can calculate the airflow; our dust extractor provide ~1000Pa pressure to your use, so the duct system pressure should known first.

Q: What type of dashing modes the de-duster provides?

A: 1:Compress air backflow cleaning type; 2:mechanical vibration dust cleaning.

Q: The dust collection unit’s power supply?

A: Every country have different industrial power supplies, we could OEM the blower for your needs.

Q: What the compressed air should supply when install the dust remover unit?

A: 0.4-0.6Mp compressed air (water and oil removed)

Our Customer Application

Pharmaceutical usage

HVAC

pulverizer

Tablet pressing

Film coating

Fluidized-bed drying

pulverizer

Tablet pressing

Film coating

Fluidized-bed drying

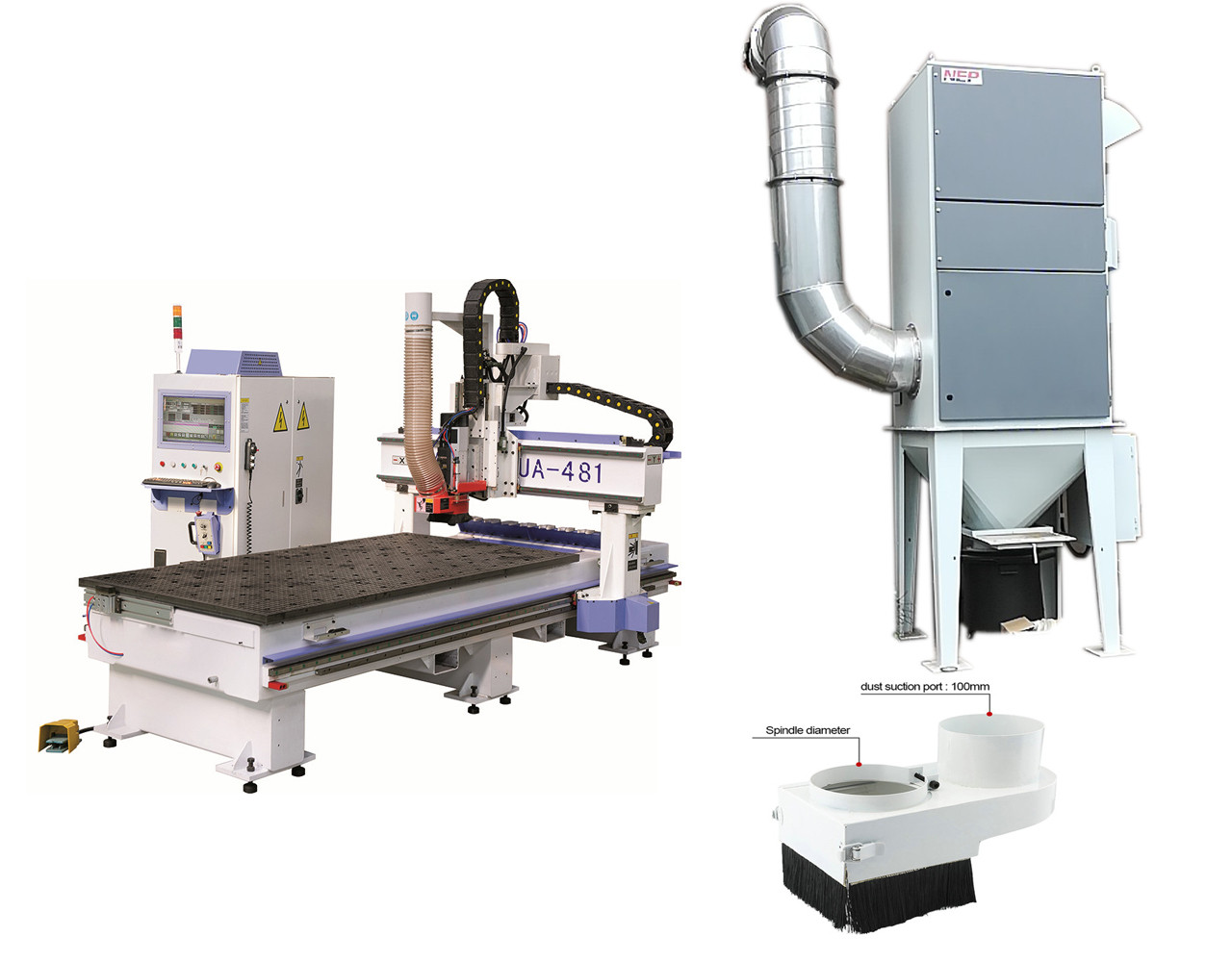

CNC metal work

Fume extractor

sand-blasting 1500-2500m3/h(CBM) dust extractor

3000CBM fiber laser cutting machine fume extractor

Carving machine

Carving machine dust extractor: 1500m3/h

Router machine

Router machine dust collector: 3000m3/h

Tablet pill pressing machine deduster

300-500m3/h 3400pa

Packing machine/powder filling machine

1000m3/h 3200pa

Contact Email: Info@dustscrubber.com