Tablet Press/Capsule Filling Deduster Cartridge Dust Extractor

- Model

- TR-15B-H

Item specifics

- Application

- Industrial Dust/fume Extraction

- Filter Material

- Polyester Cartridge Filters

- Cleaning Mode

- Pulse jet compressed air backflow

- Compressed Air Source

- 0.4-0.6MP

- Jet Control

- Timer/pulse controller

- Power Supply

- 380V/50HZ or Customize

Review

Description

Tablet Press/Capsule Filling Deduster Cartridge Dust Extractor

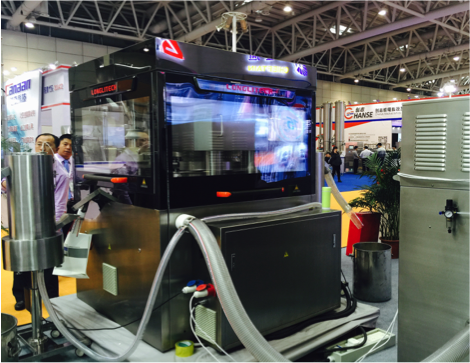

In pharmaceutical factory, besides the HVAC system, other equipments also need the dust collector to protect the machine, like high speed rotary pill tableting machine, capsule filling machine...

Especially for the tableting machine, if not extract the fine powder rapidly, it will influence the tablet manufacturing.

Normally, in sterile area, equipments need stainless steel material and easy for cleaning, without blind angle, so this dust collector's surface is smooth.

Normally, in sterile area, equipments need stainless steel material and easy for cleaning, without blind angle, so this dust collector's surface is smooth.

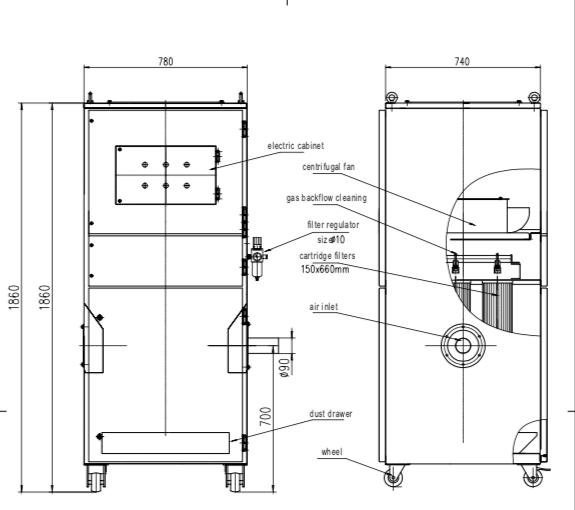

Drawing of the deduster

This dust collector is unique design for the tableting machine, the inlet is 90mm, using flexible hose to connect the tablet press machine, with extremely high pressure fan to overcome the pressure drop.

Compare with normal dust catcher, it have large filtration area to confirm the high efficiency, what's more, it have pulse jet cleaning system, instead of manual shake, it make the machine working continuously.

In addition, the centrifugal fan make less noise than normal dust extractor.

Best choice for tableting machine and capsule filling machine.

Parameter

|

Model

|

TR-10B-II

|

Full Pressure

|

3500Pa

|

|

Airflow

|

1500m3/h

|

Filter Area

|

22.5m2

|

|

Motor Power

|

3Kw

|

Filtration Efficiency

|

F9

|

|

Air Source

|

0.4-0.6Mp

|

Cleaning Mode

|

Pulse-jet

|

Filter Material | Polyester | Temperature | less than 80 centigrade degree |

Application also for :

| 1:Pill encapsulation |

| 2:Laboratory fluidized dryer and granulator |

| 3:Auto package machine |

| 4:Weighting room |

| 5:Transport |

| 6:Batch feeder |

| 7:Mixing |

| 8:Screening plant |

| 9:Cutting process |

| 10:Powder recycle |

Contact Email: Info@dustscrubber.com