Low Pressure Industrial Centrifugal Fan/Direct/ Belt/ Axial

- Model

- YFBCSL

Review

Description

High quality industrial centrifugal fan

Airflow Range: 1,000~380,000 m³/h (588~223529 CFM)

Static Pressure Range: 300~4,100 Pa (1.2~16.46 in.WG.)

Operating Temperature: -20~450 ℃

Drive Types: Direct/ Belt/ Coupling drive

Mounting Type: Base mounted

Applications: General air supply and exhaust/ Explosion-proof air supply and exhaust / Smoke removal

Advanced process

-- Steel laser cutting, precise positioning jig and all-welded technique are adopted for the blade to ensure smoothness of the margin of the blade. The welding angle is accurate, the whole blade is with strong strength, and the stress is evenly distributed during long-time high-speed operation. The operation is stable and reliable.

High balancing level

-- Each wheel is subjected to dynamic balance test. We insist to the balancing level of G4.0 (Typical products are balanced to G6.3 only). Long-term quiet and stable running of the fan is ensured fundamentally.

High-efficiency range

-- The wheel has a stable and smooth aerodynamic performance curve and owns a wide range of high efficiency working area which can efficiently avoid fan performance decrease caused by the deviation of the working point.

Non-overload

-- The series wheel exist a peak value of shaft power, when the motor is selected according to the power combined with the margin factor of motor power, the fan shaft power will not exceed the motor rated power no matter on which operation point of the stable working range the is running, then the clients can use it at ease.

Product Feature

-- To be adopted FEA-aided design for enhancing the reliability of structure.

-- Scroll and wheel with high strength and no leakage characteristics are all-steel continuous welded to improve operation safely.

-- New shaft and coupling technology to ensure precise assembly and high reliability.

-- Fan shaft is subjected to finish turning & hardening and tempering. Maximum load surpasses 35% of limit speed to ensure the long-term continuous operation of the security.

-- Bearing seal can be lubricated. Service life more than L10:80000 hours to ensure the reliability of long-term continuous operation.

-- To be configured shields and adopted bright warning color of the drive unit to ensure the personal safety of customer.

-- To be vibration tested before the fan leave the factory to achieve the requirements of long-term stable and reliable operation .

High efficiency

-- Venturi inlet matched front disc precisely to avoid turbulent flow and air leakage, so that the air flow more smoothly to improve aerodynamic performance.

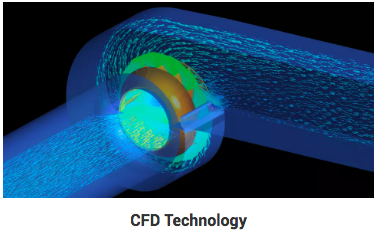

-- Optimized design repeatedly of CFD flow field simulation to ensure aerodynamic performance complied with the flow field characteristics.

-- Excellent aerodynamic performance, the maximum efficiency is up to 81%.

Humanization

-- Flexible allocationof multi-drive type.

-- Standard accessories for normal use.

-- Accessories completely to meet all kinds of application requirements.

CFD & FEA technology

ACMAN Research Institute masters a set of core CFD technology combining theory with practice owned by INFINAIR itself. In combination with our internationally accredited precision laboratories, aerodynamic parameters of the wheels and housing sizes are repeatedly optimized to pursue better air performance and sound, and now the wheels are updated to the fourth generation.

In the practice process of FEA technology for many years, INFINAIR has accumulated a lot of data and experience which are suitable for actual physical property of common materials. To ensure fan unit and all core parts highly reliable, INFINAIR has done huge computer simulation tests by FEA and actual tests to verify design parameters on our over speed, vibration and durability test platforms.