Packaging Process

- Share

Task:Packing Process must to suck in the dust from packing machines

Packing process such as powder, sugar, chemical filling in bags always creates dust to the outside atmosphere that leads to bad health to worker's especially to their lung. However, their are lot of packing machinery without a specific dust collection for different kinds of dusts.

Usually, different dust particles have different collection solutions. The flour for example, which is an explosive dust if there is full of this dust in the air and meets a spark, then there will be a disaster. Therefore a specific dust collecting solution is necessary to ensure safety. Besides, if the dust is hygroscopic or moisture, cartridge or bag filter dust collector is not enough. So powders filling in bag or bottles creates different dust which in need of different dust collecting solutions.

Pictures are the customer’s package machines that manufacture bamboo salt.

When packing machine working, there must have two points emit dust:

1st:the stock bin down unloading the materials into the packing filing machine’s tank. (See the red circle)

2nd: Packaging bag’s mouth when filing the powder.

In this process condition, if the packing machine is closed, the airflow is so small but needs high static pressure because of duct’s diameter is always 50-90mm.

So here we recommends solutions for normal dust collection.

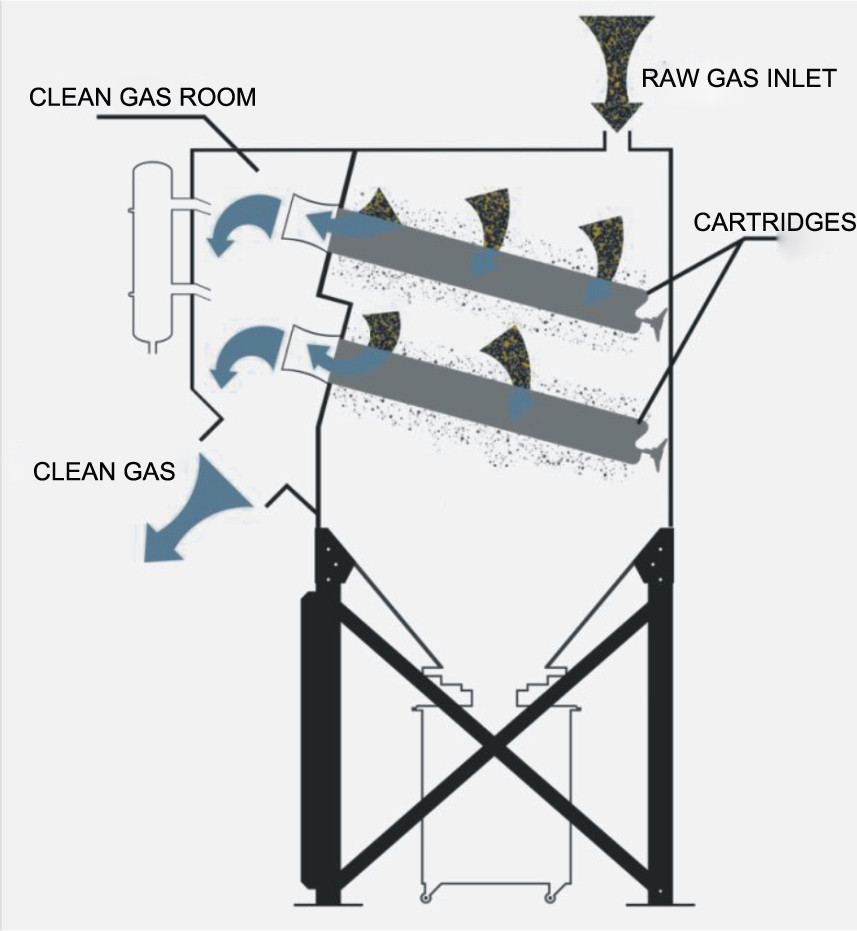

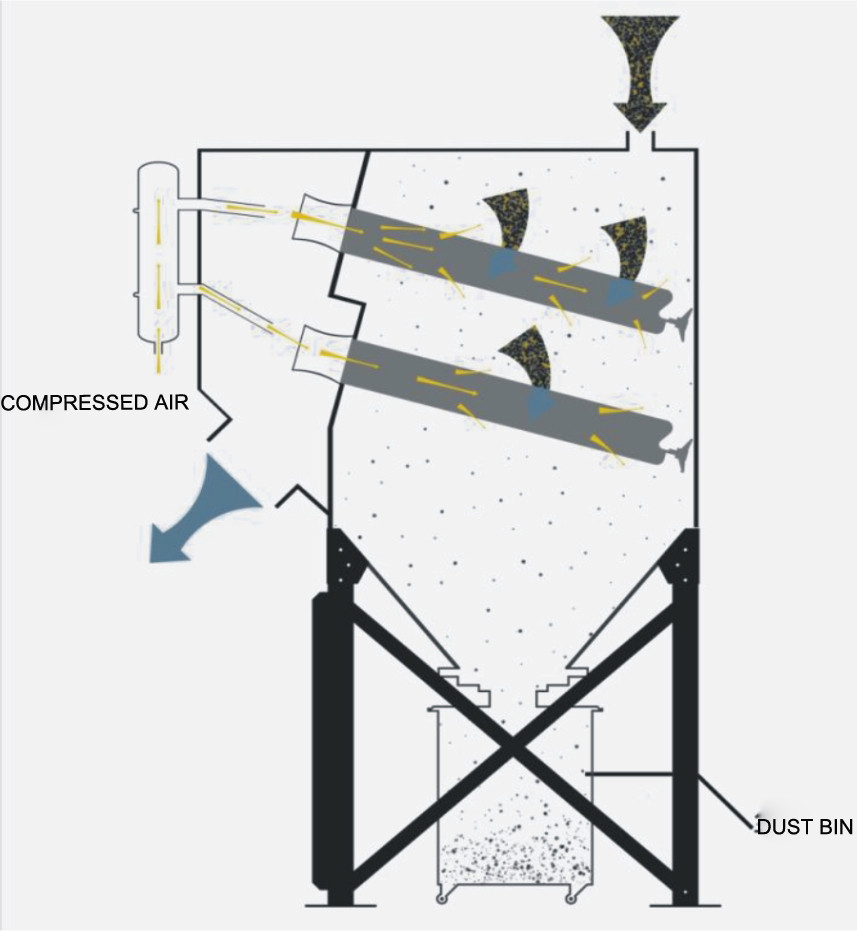

1:Cartridge packing dust collector/de duster with high static pressure, which use mechanical shaking to deash the dust.

NO. | Model | Air Volume(m³/h) | Wide | Deep | Weight(kg) |

1 | TE-2-8 | 3600-7200 | 80 | 1000x2200x3320 | 0.999 |

2 | TE-2-16 | 7200-14400 | 160 | 2000x2200x3320 | 0.999 |

3 | TE-2-24 | 10800-21600 | 240 | 3000x2200x3320 | 0.999 |

4 | TE-3-12 | 5400-10800 | 120 | 1000x2200x3790 | 0.999 |

5 | TE-3-24 | 10800-21600 | 240 | 2000x2200x3790 | 0.999 |

6 | TE-3-36 | 16200-32400 | 360 | 3000x2200x3790 | 0.999 |

7 | TE-4-16 | 7200-14400 | 160 | 1000x2200x4250 | 0.999 |

8 | TE-4-32 | 14400-28800 | 320 | 2000x2200x4250 | 0.999 |

9 | TE-4-48 | 21600-53200 | 480 | 3000x2200x4250 | 0.999 |

10 | TE-4-64 | 28800-57600 | 640 | 4000x2200x4250 | 0.999 |

11 | TE-4-80 | 36000-72000 | 800 | 5000x2200x4250 | 0.999 |