Sand Blasting

- Share

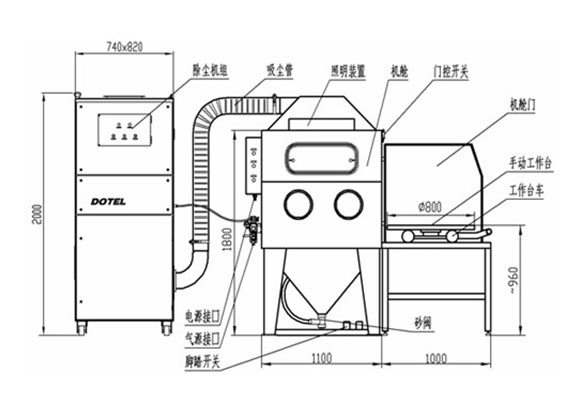

Task:Extraction and separation for blasting processes

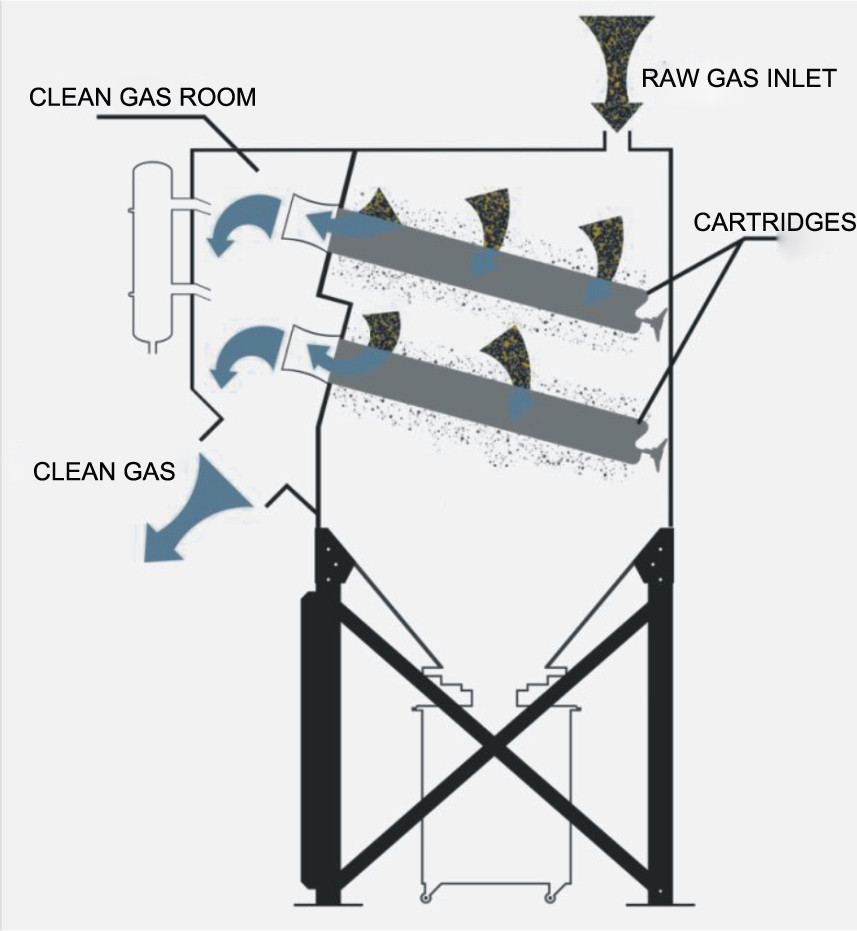

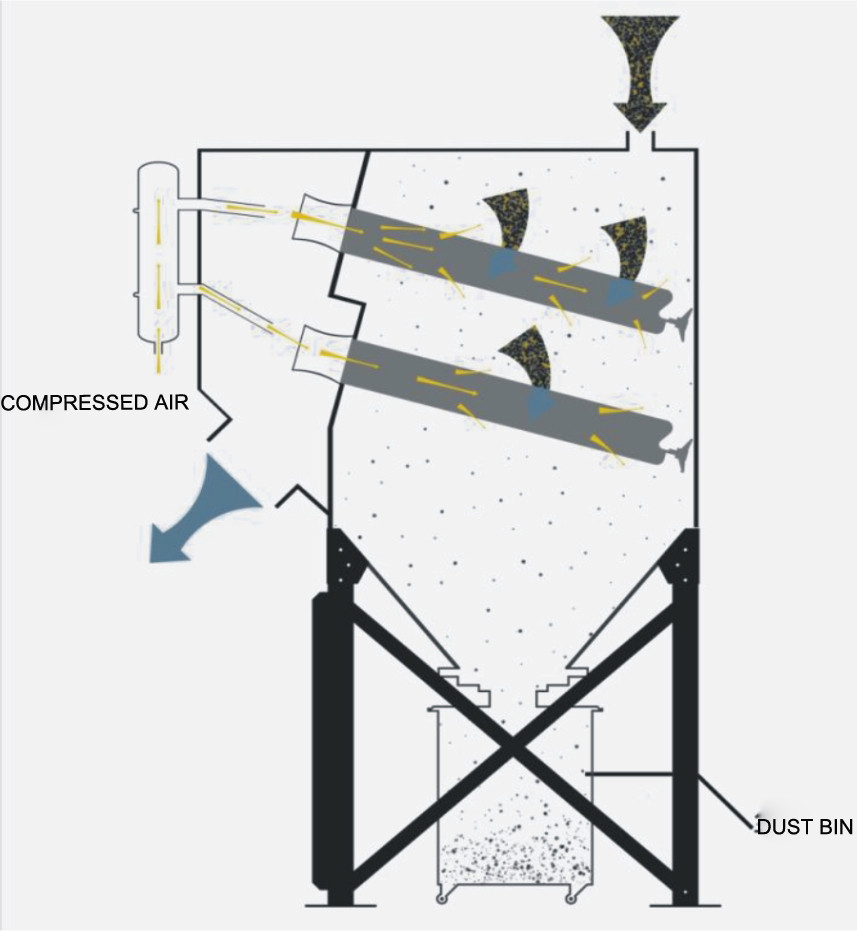

Blasting operations such as abrasive blasting, non-abrasive blasting, surface refinement blasting or shot peening create all kinds of dusts (such as steel, aluminum, plastic, ceramic, glass, etc) from mechanical abrasion.

These dusts must be thoroughly removed for the environmental reasons, and process-specific reasons.

The mixture of blasting material and blasting media generates diverse dust combinations.

When designing an extraction system, the dust features(combustible, explosive, harmful, organic or mineral, dry or oily), the applicable laws and regulations, as well as customer's request must be taken into consideration. The dust volume, the design of the blaster are all factors.

Except the extraction process, it is also necessary to clarity whether the conveving of blasting media is another influence.

Dry dust extractor and wet dust extractor all can be used to remove dust during blasting process. ACMAN provides a wide range of products that facilitate you make a right choice, and you can find an optimal balance between system technology and investment expertise as well as operating cost.

An optinal separator system shall be designed individually because of many factors(working process, installation, external factors). Various potential solutions might require extra pre-separators or fire and explosion protection measures.

NO. | Model | Air Volume(m³/h) | Wide | Deep | Weight(kg) |

1 | TE-2-8 | 3600-7200 | 80 | 1000x2200x3320 | 0.999 |

2 | TE-2-16 | 7200-14400 | 160 | 2000x2200x3320 | 0.999 |

3 | TE-2-24 | 10800-21600 | 240 | 3000x2200x3320 | 0.999 |

4 | TE-3-12 | 5400-10800 | 120 | 1000x2200x3790 | 0.999 |

5 | TE-3-24 | 10800-21600 | 240 | 2000x2200x3790 | 0.999 |

6 | TE-3-36 | 16200-32400 | 360 | 3000x2200x3790 | 0.999 |

7 | TE-4-16 | 7200-14400 | 160 | 1000x2200x4250 | 0.999 |

8 | TE-4-32 | 14400-28800 | 320 | 2000x2200x4250 | 0.999 |

9 | TE-4-48 | 21600-53200 | 480 | 3000x2200x4250 | 0.999 |

10 | TE-4-64 | 28800-57600 | 640 | 4000x2200x4250 | 0.999 |

11 | TE-4-80 | 36000-72000 | 800 | 5000x2200x4250 | 0.999 |