Laser/Plasma Processing

- Share

Laser technology is now a standard configuration in the machining industry when processing metals and organic materials (such as plastic, wood) . The increase for accuracy and productivity is also leading to increasement of pollutant, sometimes in the submicroscopic range, which influences the health of the operator and the function of the laser system. Therefore, a dedusting system is needed to ensure efficient dusting removing and separation

While conventional dry dust separator can be used for metallic and non-metallic dust, special separation processes are necessary for organic material.

While traditional dry dust collector can be used for metal or non-metal pollutants, organic materials are required special collection processing. In plasma and laser cutting process, the fume generation varies with the parameters such as, cut rates, total cutting time and material thickness.

Except the cutting consumables, surface paintcoating, base metals or any other contaminants appearing in the atmosphere is also a part of the fume composition. However, if there are no correct filtration or other dust removing measures the fume and smoke generation can be enormous

In CNC Laser Cutting Machine most particulate can be less than 10.0 microns while in laser cutting the particulates in high concentration can be less than 1.0 micron in size. In both cases, the fume or particulate is considered to be fine and a bit agglomerative when going to cool.

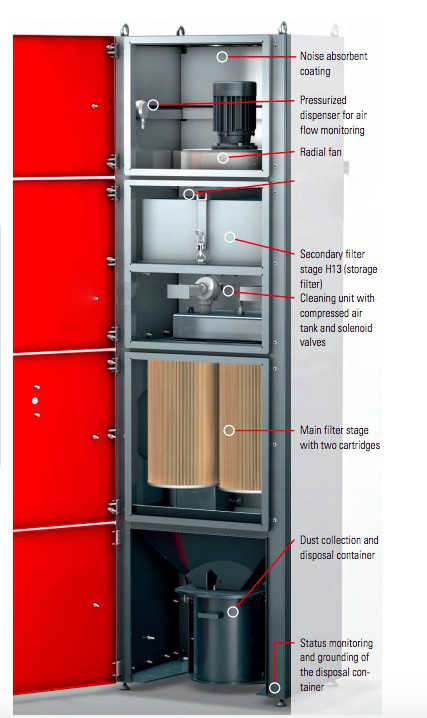

Solution:stationary cartridge filter units

Dry dust collector carridge filter series extraordinary support for ultra fine particle. whose required air flow varies based on the process and materials applied in the laser engraving. The design of the cartridge collector is flexible as for the required airflow and individual process because of the variations supplied in the filter series -also possible for large air flows. For thermal processes like laser engraving, fireproofing measures and explosion protection in the light of ATEX rules are advised. Spark collector is also suggested before the spark mixed with dust into the dust extractors, if users is not willing to replace the filter, sintered plated dust collector is a good choice.

Example:Laser Metal cutting/CNC plasma Cutting Machine Fume Extractor

Model(B) | Air volume(m³/h) | Filter(㎡) | Fan pressure(Pa) | Power(kw) | Air Source | Sound(dB) | |

Tuoer-8 | 500-900 | 12 | 1780 | 0.75 | 0.4~ | 0.6MP | 65 |

Tuoer-10 | 900-1100 | 12 | 2040-1780 | 1.1 | 0.4~ | 0.6MP | 67 |

Tuoer-15 | 1400-1600 | 18 | 2040-1780 | 1.5 | 0.4~ | 0.6MP | 70 |

Tuoer-25 | 1688-2476 | 30 | 2150-1820 | 3 | 0.4~ | 0.6MP | 73 |

Tuoer-30 | 2664-3405 | 30 | 2700-2200 | 4 | 0.4~ | 0.6MP | 73 |

Tuoer-40 | 3786-4527 | 36 | 2700-2200 | 5.5 | 0.4~ | 0.6MP | 75 |

Tuoer-60 | 4973-6457 | 48 | 2700-2200 | 7.5 | 0.4~ | 0.6MP | 75 |

Tuoer-80 | 7081-8489 | 60 | 2700-2200 | 11 | 0.4~ | 0.6MP | 78 |

Tuoer-100 | 8490-10455 | 75 | 2790-2020 |

11

|

0.4~

|

0.6MP

|

80

|

Tuoer-120 | 10400-13455 | 90 | 2790-2020 |

15

|

0.4~

|

0.6MP

|

85

|