How to Washing the Sinter Plate Board Filter Element-Delta2 Sintered Board Cleaning

- Share

- Issue Time

- Jun 16,2015

Summary

In smooth conditions, the dust collector filters do not need to wash. but in some unique conditions, the filters should be washing. Sinter-plate filters as a PE material filter...

How to Washing the Sinter Plate Board Filter Element-Delta2 Sintered Board Cleaning

In smooth conditions, the dust collector filters do not need to wash. but in some unique conditions, the filters should be washing.

Sinter-plate filters as a PE material filter which have the characteristic of hydrophobicity, could be washing regularly if have some needs.

But how to wash the sintered filter element is a technical instruction.

Here ACMAN provide a nice advice on the DELTA2 sinter plate filter cleaning.

Instructions

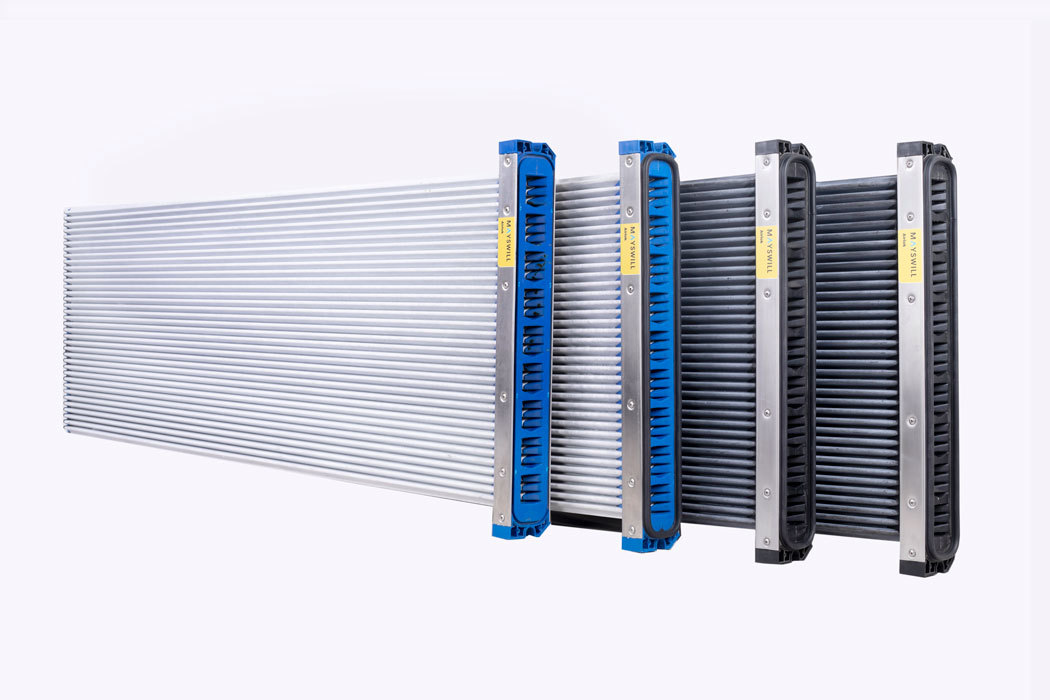

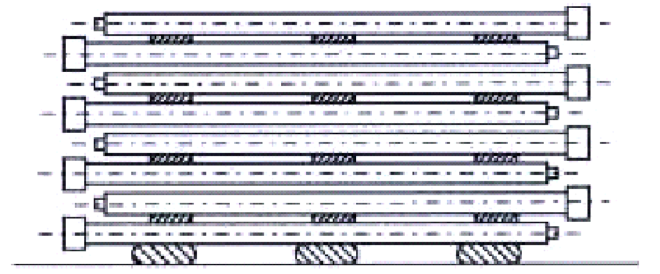

1: Taking out of the sintered plate/board filters from the dust collector. and placing the filter elements horizontally, please see the picture below: Head to tail staggered, between the filters there are liners to avoid the crash of the filters.

If there is no placing place, ACMAN suggest you to clean the filter one by one.

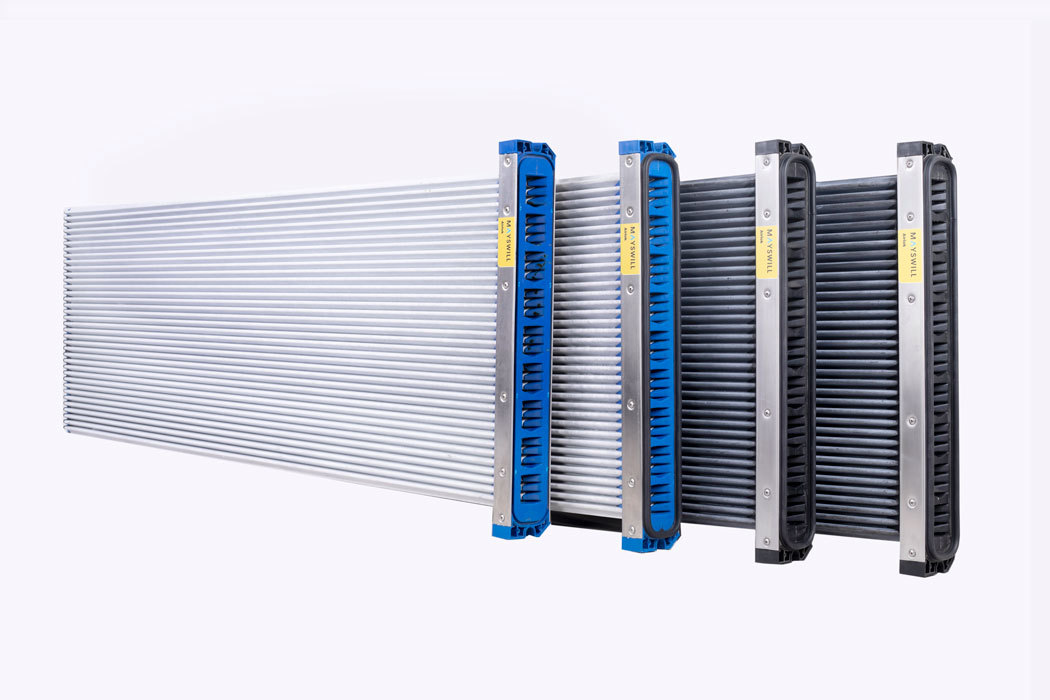

2: Taking one of the filters and setting vertically, and using the soft brush to clean the filters' surface.

3: By using cleaning water of normal temperature, the operator rinsing the water on the surface of the sintering filter element from head to tail.

4: Normally, 1-2-3 steps could clean the sintered filters thoroughly.

5: If the sinter plate filters's surface still have the dust cake, this may because of the dust harden, the operator should soak the filters in the clean water.

6: The soaking filter should be get out to wash 2-3 times.

7: The essential part is the drying process:

7.1: airing drying naturally, need 16 hours sunshine duration;

7.1: airing drying naturally, need 16 hours sunshine duration;

7.2: drying baker/room, need 8 hours drying time at the temperature of 50-60 centigrade degree.

8: Install the cleaned filter into the dust collector and testing the leackage.