DUST COLLECTOR FILTERS PRECOAT TROUBLESHOOTING TIPS

- Share

- Issue Time

- Apr 10,2019

Summary

Pre-coat is used to enhance efficiency or to provide a passivating coating which can be employed to neutralize contaminants such as fats or oils.

DUST COLLECTOR FILTERS PRECOAT TROUBLESHOOTING TIPS

Pre-coat is used to enhance efficiency or to provide a passivating coating which can be employed to neutralize contaminants such as fats or oils.

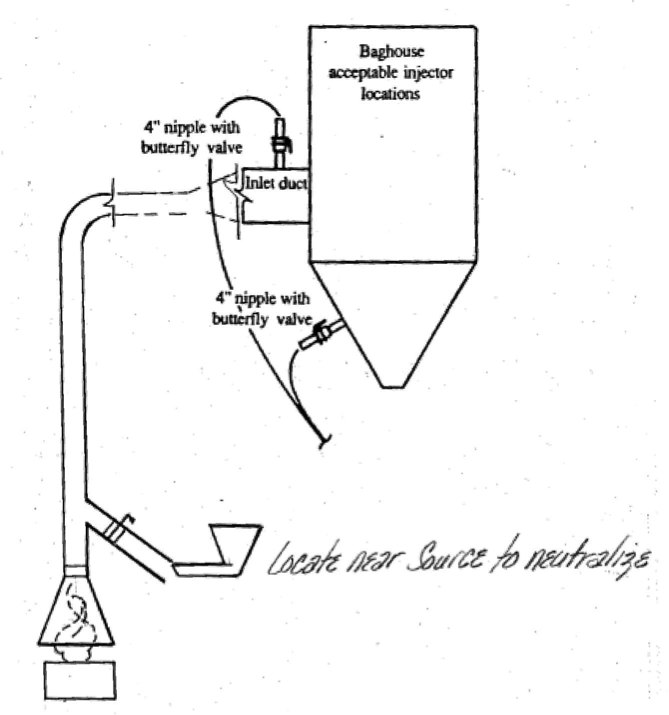

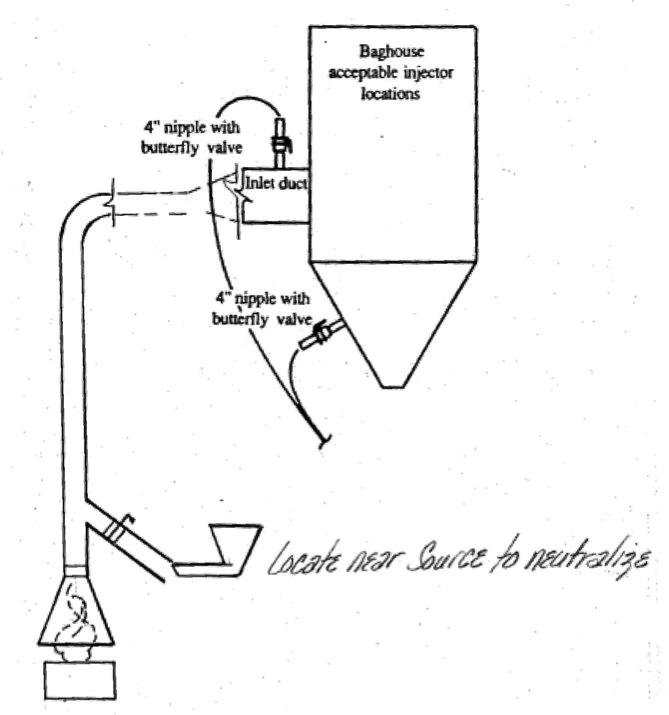

It is important to ensure even distribution of the pre-coat medium throughout the collector and filter media. This is best achieved by introducing the medium into the duct work upstream of the collector. In some cases it may be appropriate to use a continuous method of application rather than an incidental one.

We recommend three types of pre-coat medium, Limestone, Processed Limestone such as Duramite, and Neutralite powder.

Caution: Do not use products labeled Quicklime or Hydrated Lime. Hydrated lime is sometimes called Garden Lime or Agricultural Lime.

It is important to turn the pulse cleaning system off while pre-coating. Pre-coating is only effective when controlling the pulse via pressure drop. Continuous pulsing upon start-up will negate the benefit of the pre-coat.

The recommended method of applying pre-coat is

based on added pressure drop with new filters.

Note the pressure drop reading prior to adding the pre-coat. When pre-coating for enhanced efficiency, add pre-coat material until the pressure drop rises 1/2" to 1" W.G. from the initial value. When pre-coating for barrier purposes, an additional 2" to 2-1/2" W.G. pressure drop from the initial value is recommended.

Estimated volume to reach 1.5" W.G. resistance;

One pound of pre-coat per 20 square feet of cloth area.

*One pound of pre-coat per 100 square feet of pleated filter media area.*

* These are approximate values and can be used to help determine the amount of pre-coat powder required.