3 Ways to Achieve Dust-free Standard on Powder Feeding and Bag Dumping

- Share

- Issue Time

- Feb 1,2018

Summary

Dust collection system of bag dump station is needed for preventing dust emission during bag discharge.

3 Ways to Achieve Dust-free Standard on Powder Feeding and Bag Dumping

Dust collection system is used for preventing dust emission during bag discharge.

There are 3 ways to solve the problems:

There are 3 ways to solve the problems:

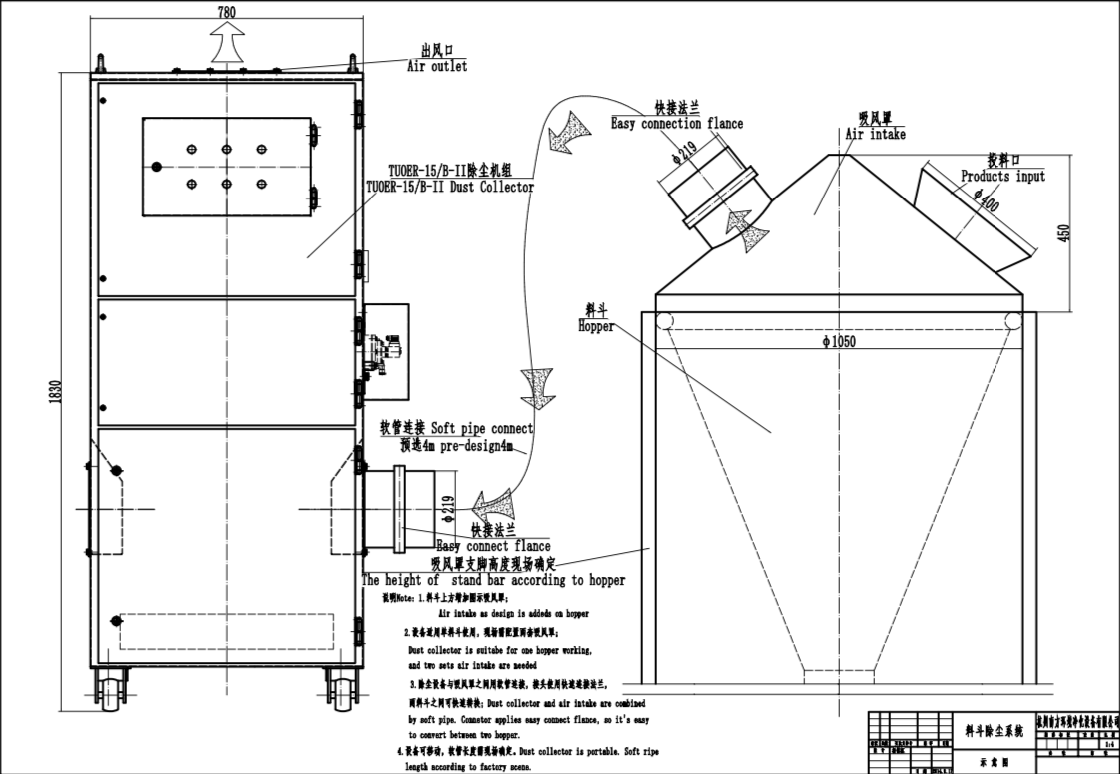

This dumping station is designed as a triangle, one side the powder put in, the other side give a negative pressure to take the emission of flying dust.

Then the dust came into the cartridge dust collector for purifying.

This system airflow is about 1500m3/h, 1500pa pressure.

the connection could use flexible hose.

the connection could use flexible hose.

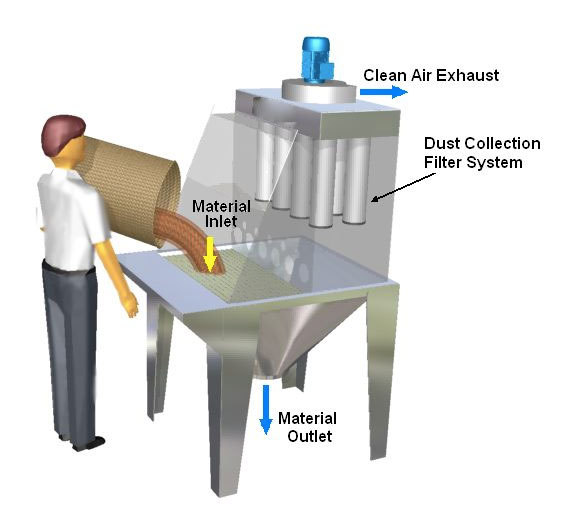

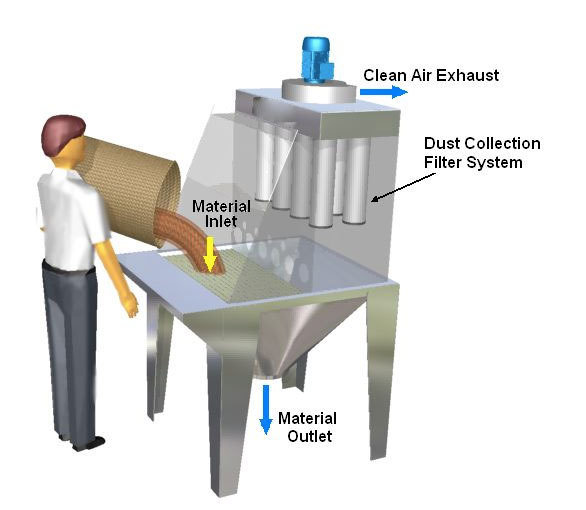

Dust-free bag dump station

This is the easiest way to bag dumping process to prevent the dust emit will shaking the sack or the powder falling down.

the blower, cartridge filters, dust hood come in one machine, the pulse-jet system will clean the cartridge filters.

The material fall in to the mixer reaction jar, the raw gas will come out, but thanks to the negative pressure and flow, won't let the dust come out to the operation side.

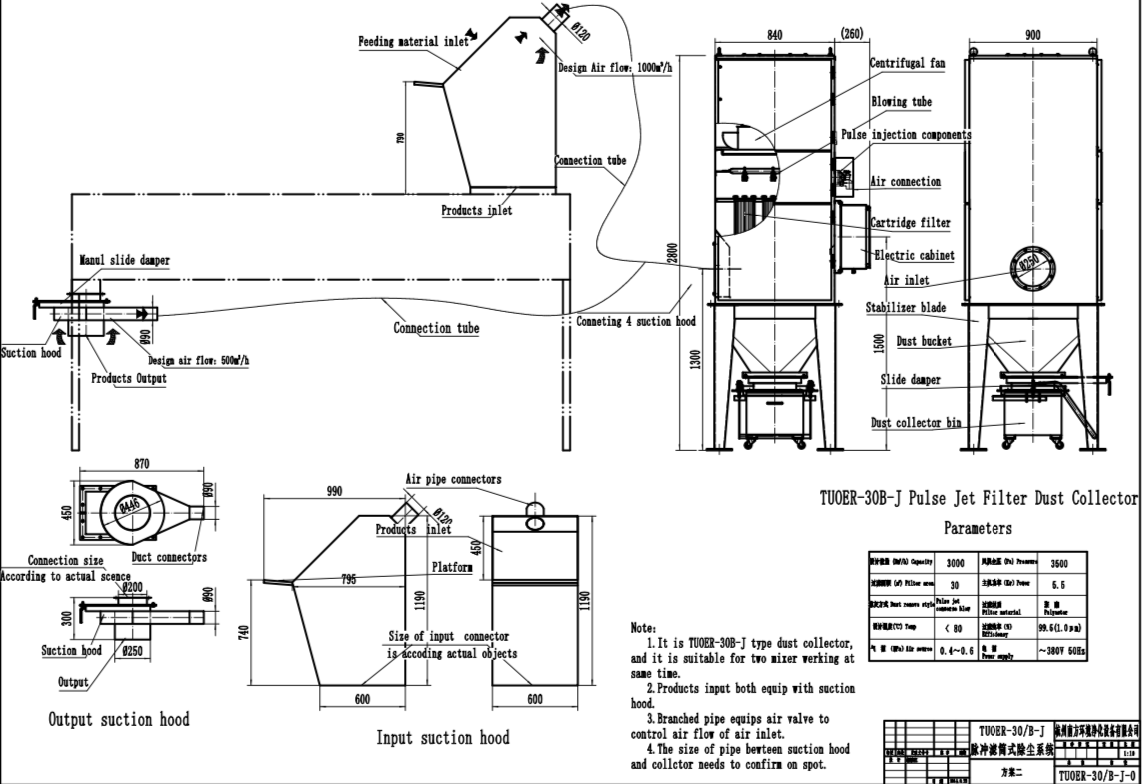

This dumping process dust collection system is a little sophisticated, it has a dumping station, also have another suction point depending on its special process.

multi-point dust collection system design, pls contact ACMAN.