Laser Cleaning Machine and Rust Dust Collector Are Good Friends

- Share

- publisher

- Lewis

- Issue Time

- Oct 30,2019

Summary

laser rust removal is a new technology in metal surface processing including rust cleaning...

Laser Cleaning Machine and Rust Dust Collector Are Good Friends

In our daily life, the appearance of laser cleaners is more and more frequent. There are many materials that can be cleaned by this type of equipment, and the application fields have become wider.

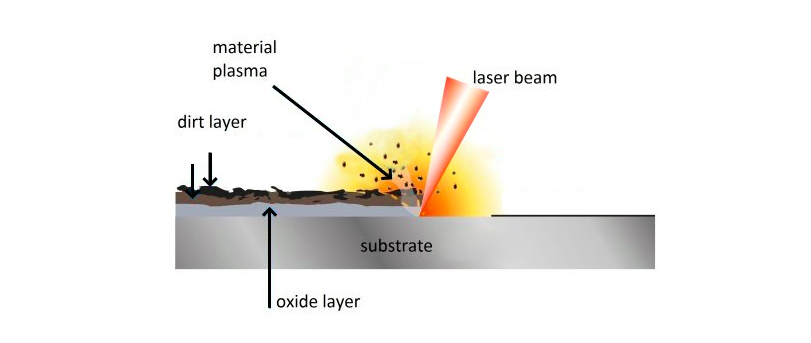

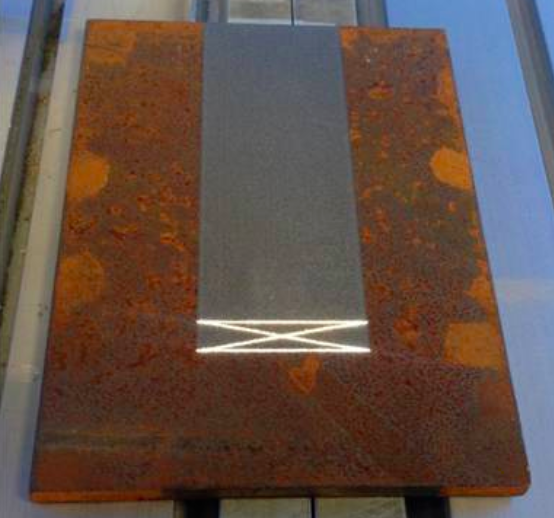

Laser cleaning applications mainly stem from the need for a non-toxic, non-abrasive cleaning method on the market. This method can be used as an alternative to the previously used chemical cleaning, manual cleaning, and abrasive jet cleaning methods. It can be used to remove the coating layer on the surface of metal or glass, and remove the paint quickly. Not only can it be completely removed, but also the surface paint layer can be cleaned layer by layer; the metal surface can be quickly derusted, and various oxides; grease, resin, and glue can be removed , Dust, stains, production residues; metal surface roughening; rust removal before vehicle parts welding, degreasing, and oxides after welding, stain cleaning; mold cleaning, such as tire molds, electronic molds, food molds; precision parts production Removal of oil stains after processing; rapid cleaning of nuclear power component repairs; oxide treatment, removal of paint, and rust during ship production or maintenance; cleaning of metal surfaces in tight spaces; cleaning of cultural relics, cleaning of stone, and external surfaces of buildings (exterior facades) Clean.

Surface cleaning

Rust Removal Laser

Stone surface cleaning

The laser can be transmitted through the optical fiber, cooperate with the robot hand and the robot to facilitate long-distance operation, and can clean the parts that are not easily reached by traditional methods. This can ensure the safety of personnel in some dangerous places.

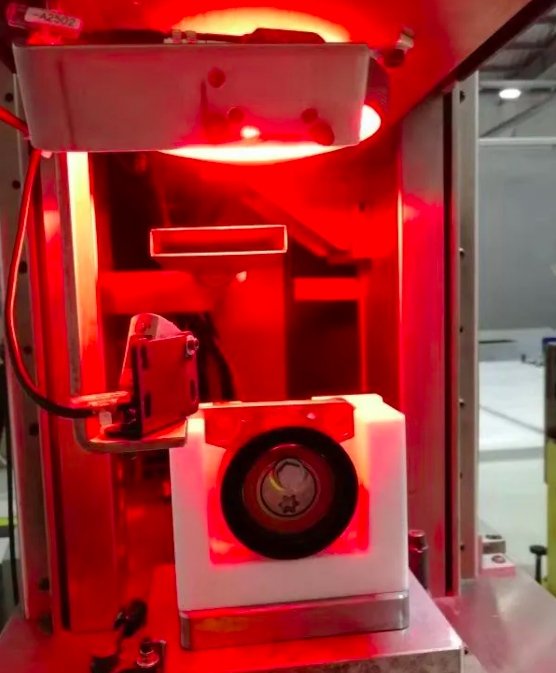

Dust Extraction

In the process of laser cleaning and engraving, the surface layer attached to the workpiece, mold, and raw materials after the laser work will peel off and fall off with the direction of the laser track. During cleaning, a lot of dust and metal impurities will be mixed out, and a small amount of lighter dust will rise. During this process, the laser cleaning machine will not produce exhaust emissions, but if the dust is not inhibited from floating in time, it will cause environmental pollution and harm to the body.

With high negative pressure dust extraction equipment, point-to-point dust removal work. A semi-enclosed space can also be constructed at the position of the work station to achieve real-time precision cleaning and matching dust collection.

Contact ACMAN

Email: Eric@dustscrubber.com

Web:www.dustscrubber.com

Web:www.dustscrubber.com