New Solution of Fume Extraction System for Die Casting Machine-300t

- Share

- Issue Time

- Aug 22,2019

Summary

Analysis on die casting machine fume and dust control.

New Solution of Fume Extraction System for 300t Die Casting Machine

Description

One of our Europe customer in Bulgaria have 5sets zinc die casting machines, which have dust and fume environment problem:

1:when the robot hand pour the zinc molten lava in to the mould, the fume came out from the mold side;

2:cleaning mode: usually, they use water to clean the mold inside with addictive lubricant, the hot mold will let the water evaporate, the zinc fume with vapor also will came out.

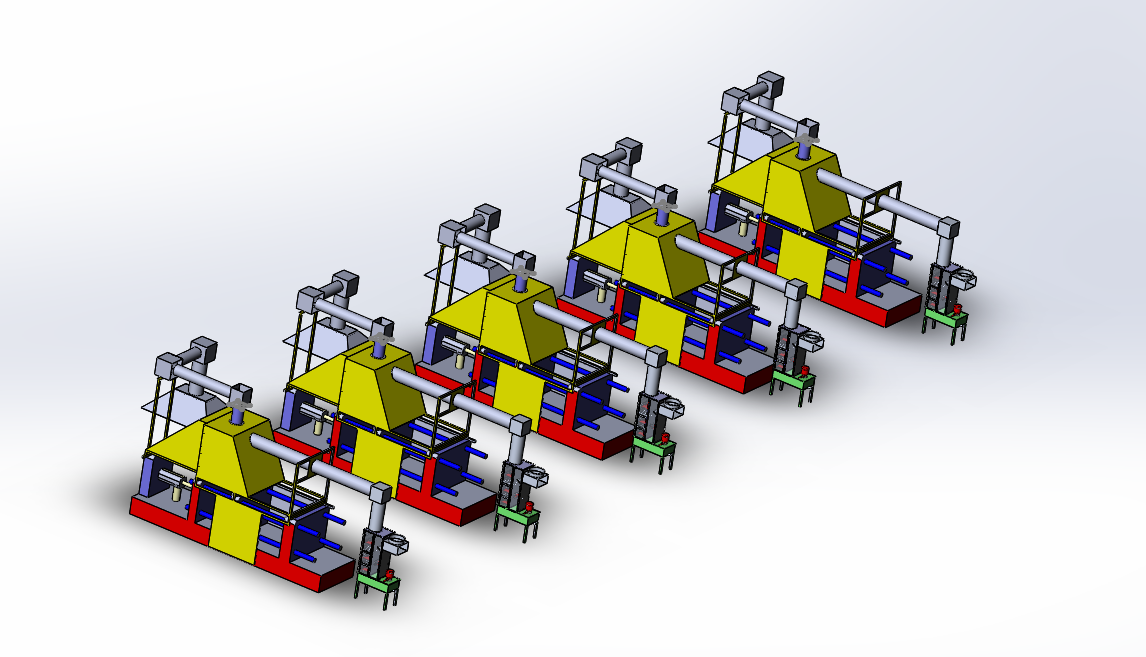

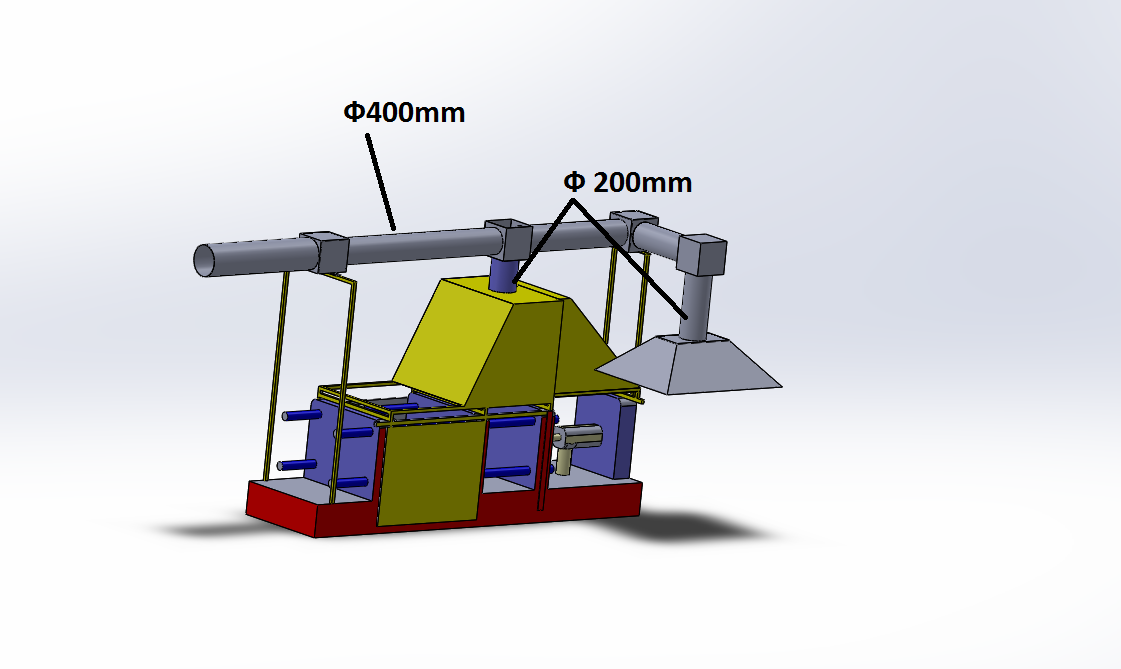

Depending on the dust points, we design the dust hood below:

2:cleaning mode: usually, they use water to clean the mold inside with addictive lubricant, the hot mold will let the water evaporate, the zinc fume with vapor also will came out.

Depending on the dust points, we design the dust hood below:

Dust collector choose

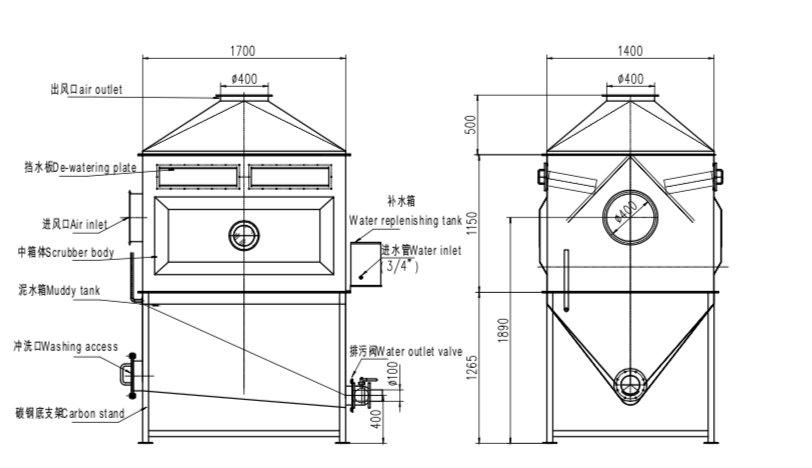

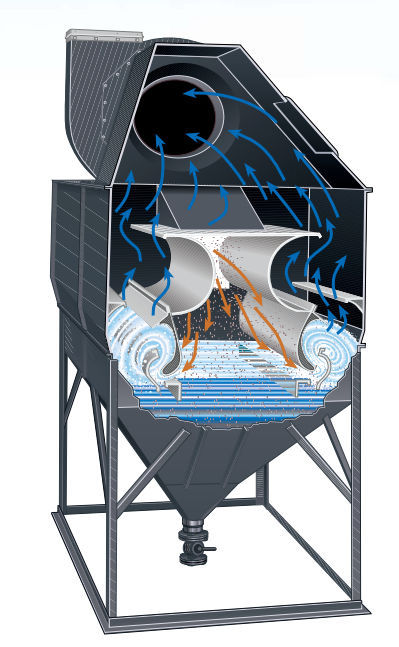

Depending on the dust categories and moisture atmosphere.

we recommend wet scrubber for the main dust collection type.

we recommend wet scrubber for the main dust collection type.

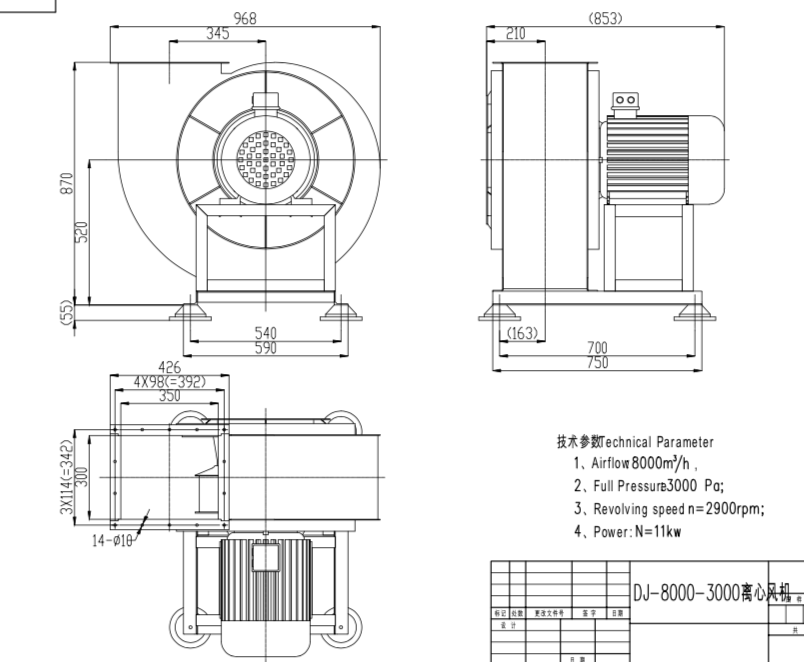

In addition, our analysis system calculate the airflow is 8000m3/h.

The zinc powder, if use dry dust extraction type, will have flammable risk. also, the safety device is expensive in dry system.

The zinc powder, if use dry dust extraction type, will have flammable risk. also, the safety device is expensive in dry system.

Contact ACMAN

Web Links:http://www.dustscrubber.com/products2095906/Wet-Scrubber.htm

Email: Eric@dustscrubber.com

Email: Eric@dustscrubber.com