Cartridge Filter Dust Collector VS Bag Dust Collector

- Share

- Issue Time

- Jun 17,2020

Summary

pulse dust collector normally have baghouse and cartridge dust extractor, they have lots of differences.

The difference between cartridge dust collector with bag dust collector-Cartridge VS Filter bags

1. The difference between filter material and principle

1. The hard filter material of the filter cartridge or filter bag is folded to form a cylinder. It has no skeleton, is short, and has a large space between the cartridges. The dust is thoroughly cleaned and there is no secondary pollution.

2. The cloth bag is sewn into a filter bag with a soft filter material, which is sleeved on a skeleton welded by steel bars (commonly known as a dragon skeleton). The filter bag is firmly densely packed. The type of filter material is long polyester fiber and its post-treatment material is mostly single layer. Ordinary industrial polyester fabric.

3. Filtration principle The principle of surface filtration: the principle of deep filtration of the dust in the filter cartridge dust collector does not penetrate into the filter material. The dust of the bag filter goes deep into the filter material, and the dust layer is established on the outer surface of the filter material to maintain the dust removal efficiency.

2. The main performance comparison

Cartridge dust collector: filter material characteristics

|

Items

|

cartridge dust collector

|

bag filter dust extractor

|

|

Filter material characteristics

|

Anti-condensation, good air permeability, ultra-fine powder, fibrous dust are not easy to pass

|

The filter material is rough, easy to stick dust, poor permeability, ultra-fine powder, fibrous dust is not easy to pass

|

|

Efficiency

|

The dust removal efficiency is as high as 99.7%-99.9%, and the work is stable, which can reduce the emission concentration, which is conducive to the control of the total emission, and is suitable for high concentration conditions.

|

The dust removal efficiency is not as high as 99%-99.5% of the filter cartridge, which is not conducive to controlling the emission concentration and total emission, and is not suitable for high concentration conditions.

|

|

Equipment Resistance

|

Low resistance, general dust, final pressure 1500PA

|

Large resistance, general dust, sometimes higher final pressure 1500PA

|

Pulse-jet air backflow system-Compressed air consumption | Backflushing force is large, uniform and good effect | The back blowing force is small, the back blowing is uneven due to the long filter bag, and the effect is poor. When the filtering air speed of the general dust exceeds 1m/min, the dust cannot be blown down. |

Air leakage rate | The equipment has few openings and the air leakage rate is less than 2% | The equipment has many openings and the air leakage rate is 5% or even higher |

Equipment size and weight | The size of installation and combination is very small, light weight can be combined by unit, and can be combined with the fan to form a unit. The upper part of the dust collector is easy to install without a working surface and takes up little space. | Large shape, bulky, single device, main fan is loose parts, large installation space, 3M high bagging space must be reserved on the upper part |

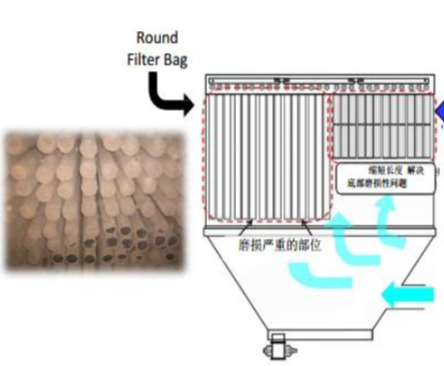

Equipment maintenance and management, service life | The filter cartridge has no mechanical wear and has a long service life during the continuous exchange of work and back-blowing, sometimes up to several years. No tools are needed to remove the filter cartridge, which is convenient for disassembly and assembly. | The filter bag and the skeleton suck one drum at a time during working and backflushing, constantly rubbing, the filter material is seriously damaged, the filter bag replacement is cumbersome, and the secondary pollution is produced after laborious effort. |

3. Economic comparison

|

Items

|

cartridge dust collector

|

bag filter dust extractor

|

One-time investment equipment fee | Advanced product performance and high production cost. But the price is the same as the old one, and some specifications are still cheap, and it is 1/4 of the price of imported products. | The price is the same as the new equipment, but the equipment is incomplete and there are no spare parts. The air leakage rate is large and the fan specifications are large. The main fan is a loose part, which increases the pipeline cost |

Supporting civil engineering, electrical and compressed air equipment | The dust collector is light in weight, small in size, saves on civil construction costs, less compressed air consumption, low requirements, and small investment in compressed air equipment | The dust collector has heavy weight, large volume, high civil engineering cost, large equipment power consumption, high cost of supporting electrical engineering, large compressed air consumption and high pressure, which increases the cost of air compressor equipment and supporting civil engineering and electrical. |

|

Maintenance costs

|

Under normal operating conditions, there is no need to change the filter cartridge, and there is no need to stop production when replacing the filter cartridge.

|

The later maintenance cost is high, the filter bag must be replaced frequently, and the cost is high. When the filter bag is replaced, the production operation needs to be stopped.

|

|

Power consumption

|

Main fan: The dust collector has low resistance, low air leakage rate, low air consumption, low air pressure, and low power consumption. Backflushing system: The amount of compressed air used is small, requiring low pressure and low power consumption. |

Main fan: The dust collector has large resistance, large air leakage rate, large air consumption, large air pressure and large power consumption. Anti-blowing system: The anti-blowing machine and the rotary arm are power-consuming equipment, which consumes a lot of power. |

|

Conclusion

|

Features of pulse filter cartridge dust collector: 1. Pleated filter cartridge to increase the filtering area 2. Improve the treatment air volume 3. Reduce the filtering air speed 4. Easy to clear dust and reduce pressure difference 5. Save compressed air 6. Easy installation and maintenance 7. Dust removal efficiency up to 99.99% |

The advantages of the pulse bag filter after transformation: 1. The filtering area increases by 3 to 5 times, and the filtering wind speed drops greatly 2. Dust removal efficiency increased to 99.99% 3. The filter cartridge is short in length and has a large excess space, which is conducive to dust settling 4. Extended life of filter cartridge 5. All Venturi tubes and cages are exempted 6. The filter elements are short and few, easy to install (top mounted), easy to repair and replace |

4. Advantages and disadvantages

4.1 cartridge dust collector advantages&disadvantages

1. Advantages of filter cartridge dust collector:

Three new: new filter material (waterproof, moisture-proof, wear-resistant and anti-corrosion), new structure (hard filter material folded layout, no reinforcement framework, no filter material wear phenomenon), new theory (surface filtration replaces deep filter dust, no longer penetrates and filters Material inside). Backward dust collectors that have been used for many years, such as reverse blowers, air box pulse blowers, and mechanical rapping units, have been eliminated by the United States, Germany, Australia and other countries. Cartridge dust collectors are the replacement products of these old dust collectors, and their advantages are as follows:

1) The dust removal efficiency of the filter on the surface of the cartridge dust collector is much higher than that of the old dust collector, which greatly reduces the emission of harmful substances. The air purification index has reached the world advanced level, completely changing the backwardness of the old dust collector. status.

2) The filter cartridge type dust collector has no filter material wear, and its body has no moving parts. It can be used for a long time without maintenance (even if the filter cartridge is replaced). It avoids the trouble of continuously changing the filter material of the old type dust collector, saving Money saves time and effort without secondary pollution.

3) The volume and weight of the filter cartridge dust collector is much smaller than that of the old dust collector of the same specification, which saves civil construction space and civil construction load, and saves significant capital construction investment.

4) The resistance of the filter cartridge dust collector is small, the compressed air consumption is small, and there is no maintenance work. Compared with all kinds of old dust collectors, it saves energy by more than 30%. No company can ignore the significant economic benefits brought by this energy-saving effect.

4.2 Bag dust collector advantages &disadvantages

1) It has the characteristics of simple operation, continuous dust removal, stable resistance, high filtration speed, no moving parts inside, simple design, etc. It is a highly efficient bag dust collector.

2) The dust removal efficiency is high, and it can collect more than 0.1UM of dust, so that the dust-containing gas can be purified to 15mg/m3 or less.

3) Less auxiliary equipment, less investment, and technical requirements are not as high as the electrostatic precipitator.

4) Capable of collecting dust that is difficult to be recovered by electric dust removal, and to a certain extent, it can collect nitrates, sulfides and other compounds.

5) Good adaptability to load changes, especially suitable for capturing fine and dry dust. The collected dry dust is easy to handle and recycle.

6) The bag-type dust collector has high safety when collecting explosion-containing or spark-containing gas.

3. Disadvantages of bag filter:

1) For different types of gas, the corresponding type of bag should be selected, and the bag needs to be replaced frequently, which consumes a large amount of bag.

2) When collecting dusty gas with high humidity, moisturizing measures should be taken to avoid "sticking bags" due to condensation, so the bag dust collector has certain requirements for the humidity of the gas.

3) The resistance is large, the general pressure loss is 1000-1500PA.

4) For high-temperature gas, cooling measures must be adopted.

5) When receiving dusty gas with a large particle diameter, the cloth bag is more prone to wear.